The world's leading trade fair glasstec 2022 - an important event for us and our customers. After what feels like an eternity, we can finally show you our innovative new products live and on site. Highlights from cericom this year are our laser cutting machine c-cut and our innovative new laser marking system c-mark.

Together with our partner company Lascom Laser GmbH, we look forward to making your visit an unforgettable experience!

For our customers and interested parties we have a ticket contingent ready - just send us an e-mail to infocericomde.

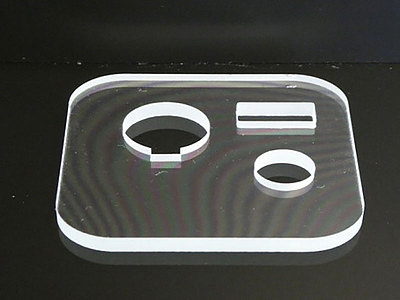

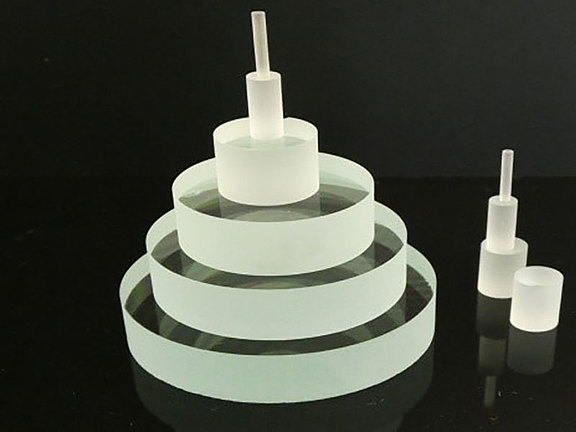

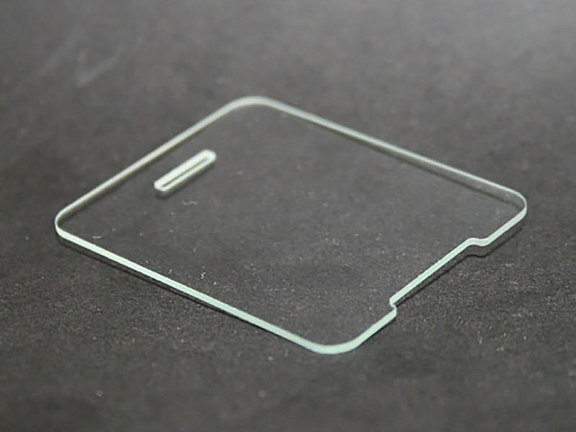

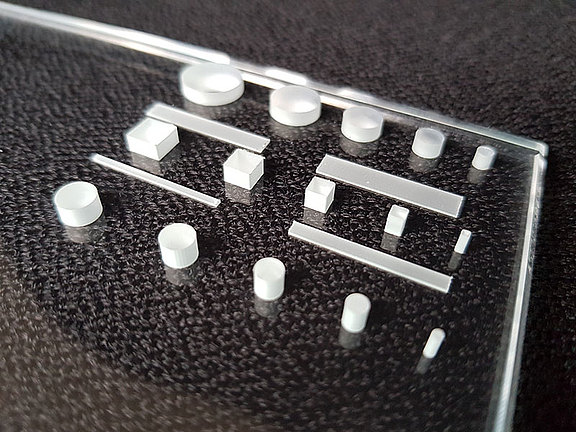

c-cut is our machine for (contour) drilling, cutting and milling of optically transparent materials using laser radiation. This machine enables efficient laser processing of all types of glass, especially float, borosilicate and quartz glass. In a working area of approx. 100 x 100 mm, holes can be made, sections can be cut along any curve and complex geometries can be milled according to CAD drawings.

A very narrow cutting width – in combination with high accuracy and resolution – enables the production of cuts, that cannot be achieved with any conventional glass processing technology.

The machine process is completely "dry", i.e. it does not require any water. Drill holes and cutting contours can be created with a high aspect ratio of up to 1:25.

Advantages:

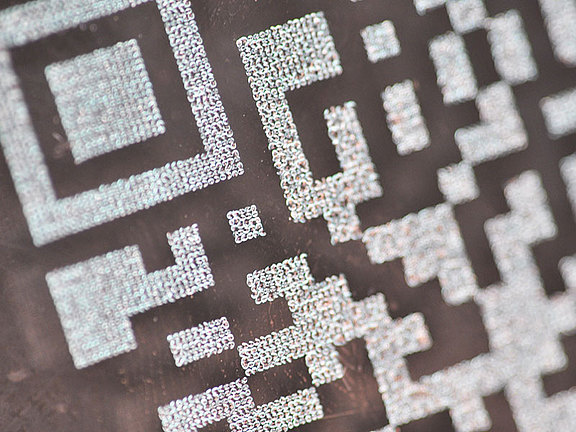

- High marking quality and durability

- Direct glass marking; no additional material required

- No weakening of the glass in the marked area

- Easy service

- Electronic readability

- Individual product code for referencing

- Highest marking speed

- High flexibility of marking motifs

- Professional software with simple user interface

- Low energy consumption

- Labeling of other materials possible

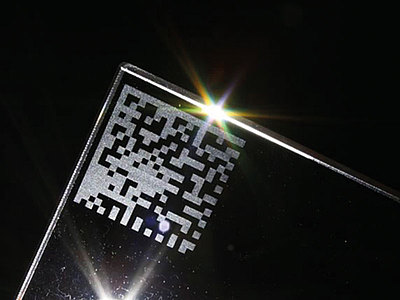

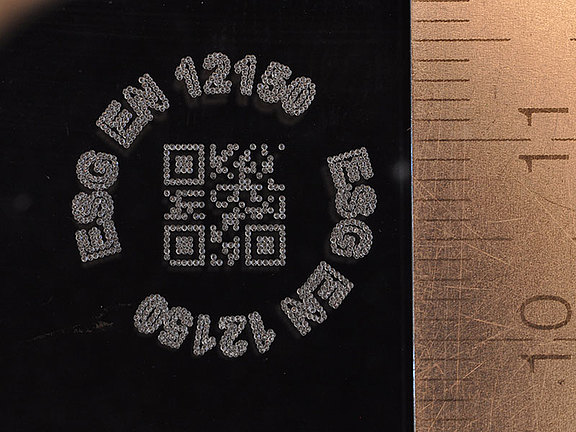

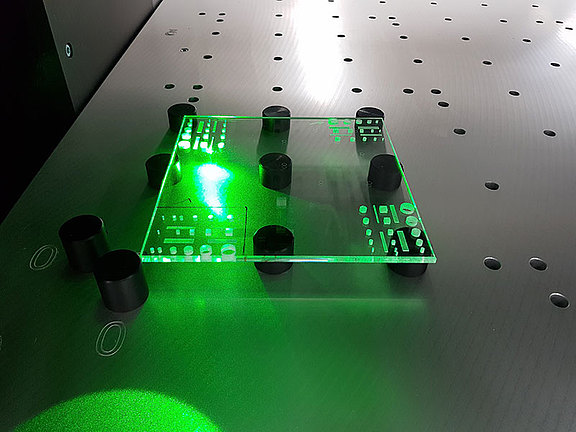

c-mark consists of a module with a laser and 2D scanner as well as a lens, optionally available with variable focal lengths. A special adapter plate enables easy and flexible integration of the laser marking module into the existing system technology and facilitates maintenance and replacement.

The rotatable laser scan head enables the laser beam to be emitted variably, so that processing can also be carried out "overhead", for example.

It can be used wherever high-quality markings are required or copyrights are an issue – for example for marking safety glass, in the automotive industry, in medical technology, or for jewelry and perfumes. c-mark enables easy integration into existing systems and machines and is also available as an alternative "stand-alone solution".

![[Translate to English:] c-cut](/fileadmin/_processed_/9/3/csm_c_cut_hintergrund_9a324696eb.jpg)

![[Translate to English:] c-mark](/fileadmin/_processed_/7/1/csm_c_mark_hintergrund_20163a3f1f.jpg)